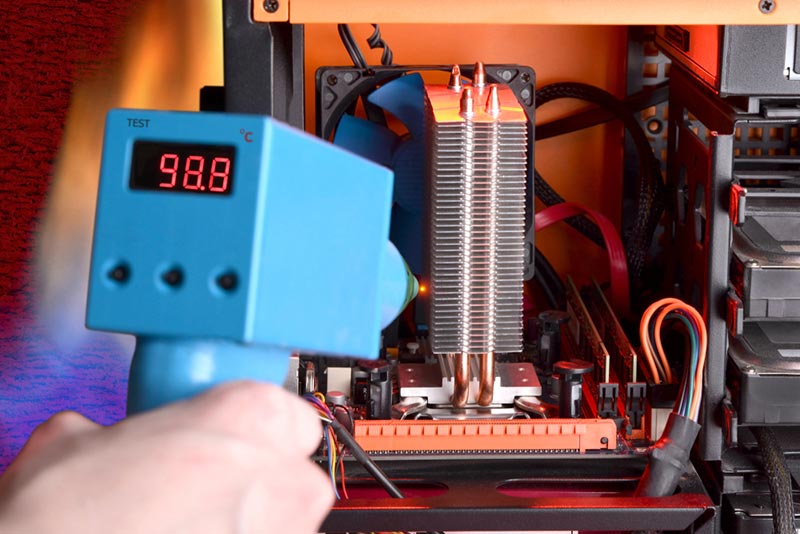

How Does a Laser Thermometer Work?

Last Updated on

Today, a lot of things have changed. We now have a wide array of options when it comes to thermometers, and these options come with many useful and exciting styles of application. The laser thermometer is a great example of what we’re talking about. They are so efficient that they have enhanced usability and significantly reduced the margins of error in various readings.

Let’s take a look at how these thermometers work.

How Do Laser Thermometers Work?

We’re almost certain that you’ve seen or even used one before, but you probably didn’t know it. Most people know it as the infrared thermometer because it’s only capable of functioning due to black-body radiation.

Black-body radiation is the radiation within an opaque or non-reflective body. This radiation is thermal electromagnetic in nature, and it’s often emitted by the body when it’s in thermodynamic equilibrium, with respect to the environment.

According to scientists, any object that has a temperature that’s above the absolute zero mark will have several molecules roaming around inside of it. If the molecules are moving faster than usual, that’s an indication that the object’s temperature is relatively high. And while they are moving, they are also emitting electromagnetic radiation, known as infrared.

Distribution Of Electromagnetic Radiation

On the electromagnetic spectrum, infrared is way below visible light. So, we cannot see this radiation. However, as the object keeps on getting hotter, more and more infrared radiation will be emitted. If it doesn’t stop, it will get to a point where we now start seeing the emission of visible light.

This is the reason why if you leave a pan on your stove unattended, with the heat on, it gets hot to a point where it glows red or white. The work of an infrared thermometer is to detect those changes in radiation and record the measurements.

Where Does the Laser Come In?

The laser has been installed in the thermometer to ensure the user accurately aims at the surface using the device. You see, for this thermometer to be effective, it has to focus on the rays being emitted by the object. Because these rays will be invisible (infrared), you’ll need a laser to guide you. Once captured, the rays will then be funneled into a thermophile, otherwise known as the detector.

It’s in this detector that the rays are converted into electrical signals, ultimately being displayed as temperature. How high or low the object’s body is will hinge on the amount of electricity produced. If the readings are high, that would mean the gadget generated and recorded high amounts of electricity. That would also mean it converted high amounts of radiation from the object in question.

The fact that infrared light is invisible doesn’t mean that it lacks the properties displayed by visible light. It can still be absorbed, reflected, and focused, and that’s why the thermopile can manipulate it.

What Are the Different Types of an Infrared Thermometer?

There are probably several types, given technology has made it possible to produce literally anything nowadays, but the most common are:

- Spot IR Thermometer: This particular one has been designed to measure the spot temperature of a surface. So, assuming you want to measure the temperature of someone’s body, you could just point the laser to their head, arm, or anywhere you find appropriate.

- IR scanning system: If a spot check won’t cut it, you could go for a large area, with the help of an infrared scanning system. This gadget is best suited for manufacturing operations, especially those that involve web processes and conveyors. The system will be strategically placed, to allow it to scan any object that passes by on a conveyor belt.

- IR thermal imaging cameras: The camera is what acts as a thermometer. And it has all the components including a laser system. It’s meant to measure temperature at various points on an object’s surface, in order to generate a thermogram—a two-dimensional image.

Where’s a Laser Thermometer Used?

Automotive Industry

You’ll never walk into an automotive production plant and walk out without seeing an infrared thermometer. These thermometers have to be part of the process because they are so effective at troubleshooting overheating issues and diagnosing the components.

In addition, they are the reason why breakdowns in operations are not so prevalent during production. As the standard operating procedure dictates, the workers are expected to conduct routine spot checks from time to time. And what do you think they normally use to perform such checks? You guessed it right, it’s the laser thermometer.

Let’s move on to the garage, where mechanics use this type of thermometer on a daily basis. Seeing as it’s a diagnostic tool, it makes life a lot easier by allowing them to take temperatures of those hard-to-reach pieces or moving parts. They don’t have to dismantle everything, take the measurement, and then start rebuilding.

Heating, Ventilation, and Air Conditioning Industry

Experienced technicians in this field can attest to the fact that a laser thermometer is an essential tool in the process of diagnosing the issues plaguing a particular heating and cooling system. Every component in that system has a unique optimal temperature. So, if one of them is malfunctioning, its temperature won’t fall within the acceptable range.

This will definitely cause a butterfly effect, as all the other parts will be affected eventually. The work of the laser thermometer, in this case, is to help the technician trace the source of the issue. You’ll find them spot-checking the components one by one, until they get to the one that’s overheating, or seems cooler than usual.

Then again, a laser thermometer is only useful in cases where the technician feels the need to perform an instant point-and-shoot check. If they are only interested in determining the air temperature around the systems, they’ll go for an air probe. Sadly, the infrared thermometer can’t measure the temperature of heated air. It needs a surface, and the air is naturally transparent.

Manufacturing

Manufacturers in all industries are concerned about two things: the integrity of their products and the efficiency of the machinery’s maintenance processes. That’s why the laser thermometer fits so well in this environment as a tool. Without it, performing quality assurance checks on the different assembly lines will feel like an uphill climb.

And on top of that, they’ll keep experiencing costly equipment malfunctions, as no worker will wish to be assigned the task of routinely inspecting the pieces of equipment. These environments require a non-contact thermometer, and our laser gadget is the right tool for the job. From a distance, they’ll be able to check the power transmission, condition of the circuit boards, and even pick out loose connectors.

Home Use

The work of the laser thermometer doesn’t just begin and end at the factories. It has several other potential uses back at home as well. Haven’t you ever found yourself wondering what kind of tool you could use to check for poorly insulated sections of your house? Well, this instrument right here is all you need to detect the differences in the wall temperatures.

If the readings are telling you that the bedroom walls are cooler than the ones in the living room, that could only mean one thing—the living room is well insulated, while the bedroom isn’t.

You might also need it when you’re working on a particular DIY project, or while cooking. Of course, you cannot stick it inside the meat, but you could take the temperature of the grill before starting.

Advantages of a Laser Thermometer

Accuracy

In our opinion, any thermometer that’s not accurate is defective. Even if the margins are small, it’s still flawed, and should not be used. You don’t have to be Einstein to realize a 0.1 temperature difference can bring about a massive change in any operation.

Fortunately for us, the laser thermometer has an incredible reputation if we’re talking about the accuracy aspect. As long as you use it the way it’s intended, there will be no reason to doubt the information it provides.

Safety

Some of the objects that we’re often forced to check are not always safe. And the thing about these radiations is, even if they tell you they are practically harmless, you can never be too sure. But with the laser thermometer, you don’t have to worry about all that. If you feel some type of way about an object, you could just maintain your distance, not put yourself at risk, and still take the readings.

Avoiding Contamination

While the infrared thermometer is not the ideal device to be used in the food and service industry, it’s still useful. Its remote applicability, the same aspect that makes it a liability, is what makes it an asset in this business. Just take a second to think about it. You would want to see someone sticking anything into the food that you’re going to eat?

Even if you’re 100% certain that that instrument has been properly sterilized, it still leaves a bad taste in the mouth—no pun intended.

Durability

It’s safe to assume that any tool that can be used in a manufacturing plant, in a hospital, at home, and even in an educational setting where teachers and kids constantly drop things, is a durable piece of equipment. It’s built to withstand any form of abuse subject to it, including the effects of chemical substances.

Disadvantages Of a Laser Thermometer

Pricing

The price tag on the infrared thermometer has always been higher in comparison to other gadgets. And we think that’s due to the level of technology applied in its production. Even though it’s a simple concept, the components are remarkably advanced.

Inaccurate Readings

If you’re planning to purchase a laser thermometer, don’t go for the low-budget options. their integrities are always questionable and that can be confirmed by the readings. For obvious reasons, the accuracy of the measurements is normally off by a few degrees.

Not Dustproof

A laser thermometer is not dustproof. You have to clean it from time to time if you wish to get accurate readings. And the same applies to the surfaces of the objects in question. If they are not clean by the time the measurements are taken, the readings will be compromised.

Frequently Asked Questions (FAQs)

What’s a Distance-To-Spot Ratio?

Simply put, the distance-to-spot ratio is the distance between the laser thermometer’s user and the object being measured. There’s no standard distance, as some thermometers are more powerful than others.

Let’s say you’re working with a thermometer that has a distance-to-spot ratio of 50:1. That would mean you could even stand 50 inches away from your object, and still be able to get accurate readings on a one-square-inch area. If you can only access an 8:1 thermometer, you’ll have to move closer to the object to measure the same area.

What’s Emissivity?

This is an important aspect, as it tells you how efficient an object’s surface is at releasing thermal radiation. The emissivity of an object is always a number that ranges from 0 to 1. If it’s a 0, that’s a confirmation that your object is a shiny mirror. But if it’s a 1, it’s a blackbody.

0 also means that your object doesn’t emit any IR radiation, while 1 is reserved for objects that fall under the “perfect emitter” category. Perfect emitters are good at radiating an object’s real temperature.

All laser thermometers have emissivity settings. And these settings have to be recalibrated from time to time, to match the target’s emissivity. That’s how you get your accurate measurement.

Is It Possible to Measure the Temperature of An Object Behind Glass or Clear Plastic?

Nope. You’ll still get your reading, and they’ll be accurate, but the measurement will be that of the glass or plastic. For this device to do its job, it has to have an unobstructed view. Otherwise, you’ll just be getting unusual readings.

Final Thoughts

So, this is a recap of what we’ve learned today. First off, the laser thermometer is what we also call an infrared thermometer. Secondly, because the beam bounces off surfaces, it cannot be used to measure the interior temperature of any object—only the exterior. And lastly, it’s one of the best thermometers on the market.

Featured Image Credit: joelpc, Shutterstock

Table of Contents

- How Do Laser Thermometers Work?

- Distribution Of Electromagnetic Radiation

- Where Does the Laser Come In?

- What Are the Different Types of an Infrared Thermometer?

- Where’s a Laser Thermometer Used?

- Advantages of a Laser Thermometer

- Disadvantages Of a Laser Thermometer

- Frequently Asked Questions (FAQs)

- Final Thoughts

About the Author Robert Sparks

Robert’s obsession with all things optical started early in life, when his optician father would bring home prototypes for Robert to play with. Nowadays, Robert is dedicated to helping others find the right optics for their needs. His hobbies include astronomy, astrophysics, and model building. Originally from Newark, NJ, he resides in Santa Fe, New Mexico, where the nighttime skies are filled with glittering stars.

Related Articles:

How to Clean a Refractor Telescope: Step-by-Step Guide

How to Clean a Telescope Eyepiece: Step-by-Step Guide

How to Clean a Rifle Scope: 8 Expert Tips

Monocular vs Telescope: Differences Explained (With Pictures)

What Is a Monocular Used For? 8 Common Functions

How to Clean a Telescope Mirror: 8 Expert Tips

Brightfield vs Phase Contrast Microscopy: The Differences Explained

SkyCamHD Drone Review: Pros, Cons, FAQ, & Verdict